Combined checkweigher and metal detector

DESCRIPTION

Technical Description

It is specifically designed for high demand of weight accuracy, stability and intelligent operation. On bases of core invention patents and patented self-adaptable algorithm, plus with combination of the world’s famous component units, integrated circuits and high precision CNC structural frame, SW series check weighters contribute the leading weight inspection performance in the industry.

Reputed Components

1.German HBM fast load cell

2.Metal detector head by hardfill

3. Japanese Oriental motor

4. Danish Danfoss frequency converter

5. Japanese Omron optic sensors

6. French Schneider electric unit

7. US Gates synchronous belt

8. Japanese SMC Electromagnetic valve

9. Wein view industrial touch screen display

10 .High precision structural components by CNC

11. Stainless steel 304 frame

Advanced Technology

- German high-speed Load Cell with fast weighing speed.

- Detector is made by hard filling technology with better stability.

- FPGA hardware filter with intelligent algorithms, excellent processing speed weighing.

- Multiple filtering algorithm, X – R orthogonal decomposition algorithm, stronger

- anti-interference against metal detection.

- Intelligent self-learning technology and auto parameter settings, simple to setup.

- Ultra-fast dynamic weight tracking and automatic compensation technology effectively.

- Improve the detection of stability.

- DDS and DSP technology improve metal detection sensitivity and stability against metal including Iron, Stainless Steel, Copper, Aluminum.

- Storage of 50 product programs

- Data log in large capacity with traceable data output.

- CNC machining of structural components, excellent dynamic stability

- 304 stainless steel frame, strong and durable.

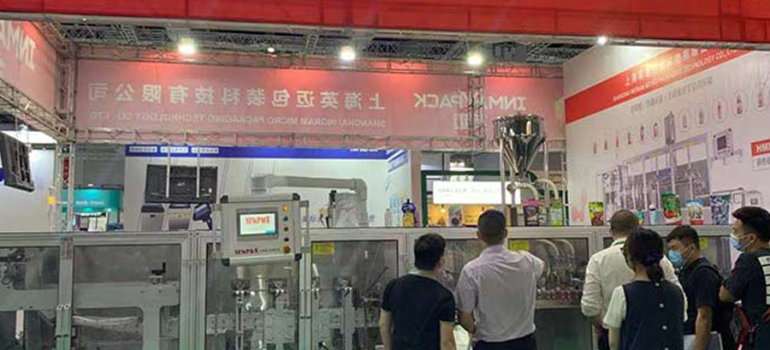

About the company :

Shanghai Yingmai packaging technology is a high-tech enterprise integrating R & D, production, sales and service of automatic self-supporting bag packaging system. The automatic self-supporting bag packaging equipment is a packaging process system that enables the roll film bag making to form, fill and seal the finished self-supporting bag. It is mainly composed of uncoiler, bag making machine, filling system and sealing device.

The company takes the concept of “leading the development of China’s independent bag packaging technology” as its corporate mission. At present, more than 40 patented technologies and software copyrights have been owned and applied for. The company’s products have passed ISO 9001 international quality system certification, 14001 environmental management system certification and EU CE certification. In the field of self-supporting bag flexible packaging, it has domestic leading R & D and manufacturing capacity and leading technical advantages

Our exhibition :