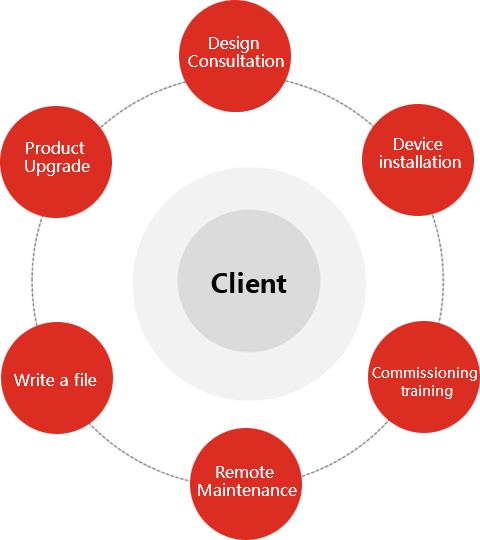

Service System

Service measures

In order to solve the problem of high technical content, complex operation, and high maintenance difficulty caused by non-standard customized equipment, the South China Technical Service Center and the Western Technical Service Center have been established, with the principle of nearby service and a stable and fast spare parts stocking and distribution network. Customers provide fast and convenient after-sales service. At the same time, it can produce and provide verification documents that meet GMP certification requirements according to customer requirements, assist customers in related certification, and maximize customer value with high-quality services. Spread Ingram Micro’s innovative spirit and manufacturing culture to the world with the concept of “cooperation and win-win, creating the future together

Service measures

In order to solve the problem of high technical content, complex operation, and high maintenance difficulty caused by non-standard customized equipment, the South China Technical Service Center and the Western Technical Service Center have been established, with the principle of nearby service and a stable and fast spare parts stocking and distribution network. Customers provide fast and convenient after-sales service. At the same time, it can produce and provide verification documents that meet GMP certification requirements according to customer requirements, assist customers in related certification, and maximize customer value with high-quality services. Spread Ingram Micro’s innovative spirit and manufacturing culture to the world with the concept of “cooperation and win-win, creating the future together

Enzyme Drink

The packaging of enzyme products is the most extensive application of this equipment. The product feature is good fluidity and requires high temperature filling. Based on the original ketchup filling, the maximum filling temperature of our enzyme products can reach 92℃

The packaging of enzyme products is the most extensive application of this equipment. The product feature is good fluidity and requires high temperature filling. Based on the original ketchup filling, the maximum filling temperature of our enzyme products can reach 92℃

Fruit Juice

The cold filling of pure fruit juice and fruit pulp products at low temperature is another important step for self-supporting pouch filling after enzyme beverages. This series of products adopt ultra-high pressure cold sterilization process, and the bag pressure can reach 600MPa. Need to control the amount of residual air in the bag.

The cold filling of pure fruit juice and fruit pulp products at low temperature is another important step for self-supporting pouch filling after enzyme beverages. This series of products adopt ultra-high pressure cold sterilization process, and the bag pressure can reach 600MPa. Need to control the amount of residual air in the bag.

Special medical food

Special medical foods are used as edible supplements to medicines, with full consideration of the control of the loss of product nutrients. It is necessary to meet high cleanliness levels in the production process.

Special medical foods are used as edible supplements to medicines, with full consideration of the control of the loss of product nutrients. It is necessary to meet high cleanliness levels in the production process.

Yogurt, Probiotics

With the improvement of the cold chain transportation and storage system, the soft packaging of NFC juice, yogurt containing fruit pulp, and parasitic fermented milk in the cold chain system is becoming more and more popular. Ultra-clean filling of yogurt in suction bags suddenly emerges

With the improvement of the cold chain transportation and storage system, the soft packaging of NFC juice, yogurt containing fruit pulp, and parasitic fermented milk in the cold chain system is becoming more and more popular. Ultra-clean filling of yogurt in suction bags suddenly emerges

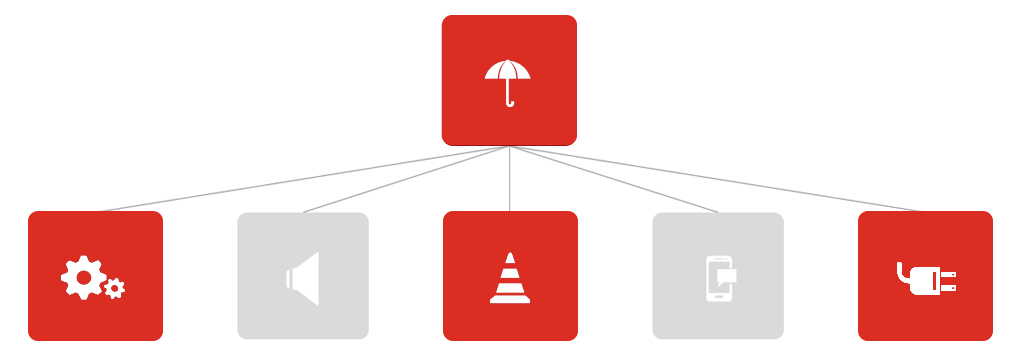

Project consulting planning

Turnkey project design and installation

Packaging material selection and consultation

Overhaul and maintenance of production line

Small batch product processing

Reason for choosing

Profession: The equipment is specially designed for soft bag liquid filling, with a cleaning tank, and the waterproof design can meet the requirements of equipment cleaning.

Focus: Focusing on the filling of stand-up pouches for liquids and sauces for 10 years. Whether it is configuration selection or product design, it is carried out around the needs of customers.

Quality: solid design derived from European style. The self-weight of the frame reaches 2 tons, and the weight of the whole machine reaches 3.5 tons, which is as stable as a rock. The unique multiple heat sealing device and water cooling system can easily obtain high-quality sealing effect and appearance.

Efficient: The maximum production efficiency of double-out special-shaped bags is up to 120 bags/min. Four stand-up pouches can reach up to 240 bags per minute.