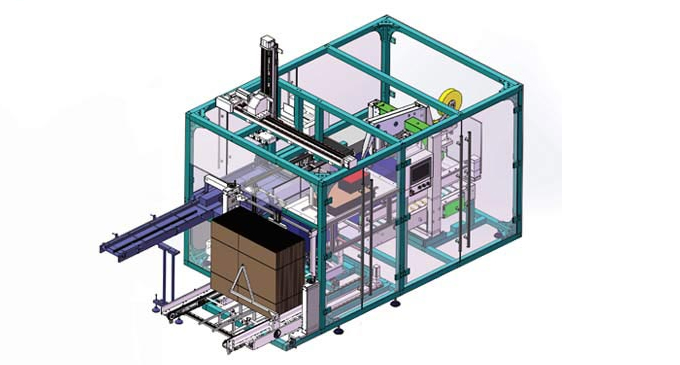

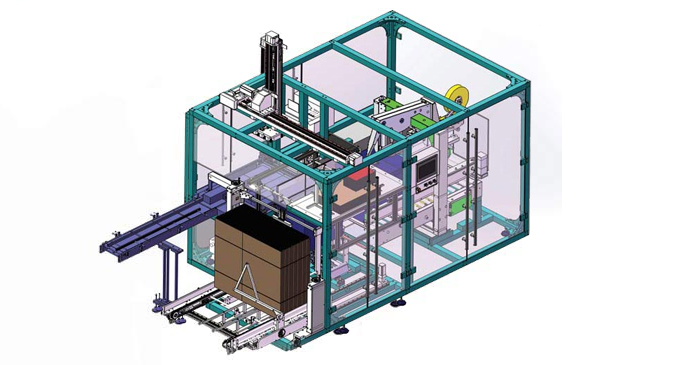

Automatic carton packaging machine

DESCRIPTION

Equipment workflow:

The materials are transported to the designated location by the connecting conveyor belt to wait for packing, and the carton is unpacked by the unpacking mechanism to wait for packing.Load the lower cardboard through the cardboard packing mechanism, pack the cardboard through the packing mechanism, then load the upper cardboard, and then enter the packing mechanism to seal the cardboard after the packing is completed.

Main innovation points:

Beautiful and generous for all aluminum body with streamlined protective door.

Integrated design of fully automatic packing machine.

The concept of modularity applies to a wide range of applications.

Quick and intuitive specification adjustment instructions.

Equipped with various monitoring devices to ensure safety and stability.

Four servo control system, to ensure the accurate movement of the position.

It is convenient to change the gripper and adapt to different products

The whole machine is in full compliance with GMP standard.

Main technical parameter

| HMK-1600 | ||||

| Machine operation | HFFS | Horizontal form fill and seal | ||

| Technology concept | Pouch origin | Form the reel | ||

| Pouch transport system | intermittent | |||

| Construction | Machine frame | SUS304 apparance | ||

| parts | SUS304 and Aluminum Alloy | |||

| Parts in contact with product | SUS316L /SUS304 | |||

| Reel | Reel diameter | 600mm | ||

| Reel Width | 720mm | |||

| Reel core | 76mm | |||

| Machine dimensions | Length×width×height | 5100×1150×2500mm | ||

| Machine weight | 3500Kgs | |||

| Pouch dimensions | Length×width×height | Minimum size | Maximum size | |

| Flat bag | 70×110mm | 180×320mm | ||

| Doypack | 70×110×(22+22) | 180×320×(48+48) | ||

| Packaging speed (pouches per minute) And pouch volume (ml) |

Speed maximum(ppm) | Volume maximum(ml) | ||

| Flat bag | 60 | 500 | ||

| Doypack | 60 | 1500 | ||

| Consumption | Electrical | 11kw | ||

| Air consumption | 300L/min 0.6Mpa | |||

| Electrical Data | 200-415V/50-60Hz/N+G

(According to customer requirements customization) |

|||

▲The machine may improve the technology without prior notice. The photos are for reference only. The material object shall prevail

About the company :

Shanghai Yingmai packaging technology is a high-tech enterprise integrating R & D, production, sales and service of automatic self-supporting bag packaging system. The automatic self-supporting bag packaging equipment is a packaging process system that enables the roll film bag making to form, fill and seal the finished self-supporting bag. It is mainly composed of uncoiler, bag making machine, filling system and sealing device.

The company takes the concept of “leading the development of China’s independent bag packaging technology” as its corporate mission. At present, more than 40 patented technologies and software copyrights have been owned and applied for. The company’s products have passed ISO 9001 international quality system certification, 14001 environmental management system certification and EU CE certification. In the field of self-supporting bag flexible packaging, it has domestic leading R & D and manufacturing capacity and leading technical advantages.

Our exhibition :