Automatic Blister Packing Machine

DESCRIPTION

Product Description:

DPP-260 Automatic Blister Packing Machine is the most advanced machine in China market, it is suitable for AL-PVC and AL-AL packing, and widely used for tablet and capsule blister packing in pharmaceutical factory, it is the high speed machine with the function of running stable, All the main parts are made of high grade stainless steel and ALU-alloy material, and machining by advanced high precise tolling machines (CNC milling machine, wire cutting) which elides disadvantage of traditional lock smith process in precision and retain finishing texture reveal sense of honor. Exquisite Camber transparent cover (assures safety operation) and draw bench treated stainless steel door adds the elegant visualize and art charm of machinery, also it is in accordance with GMP requirement.

Video Introduction

Machine Parameters:

|

Item |

Parameter |

|

|

Cutting Speed |

25-60 times/min |

|

|

Capacity |

6000-14000 sheets /hour |

|

|

Stroke Range |

30-120 mm |

|

|

Max. Forming Area |

260×120mm |

|

|

Max. Forming Depth |

22mm |

|

|

Power Supply and Total Power |

380V 50Hz 8.5KW |

|

|

Main Motor Power |

1.5KW |

|

|

Cooling system |

Condensate or water cooler |

|

|

Packing Material |

Medicinal PVC |

(0.25-0.5)x260mm |

|

PTP Alu-foil |

(0.02-0.035)x260mm |

|

|

Machine Dimension (L×W×H) |

4460×760×1620mm |

|

|

Machine Packing Size (L×W×H) |

5050×1170×2150mm |

|

|

Machine Weight |

1850Kg |

|

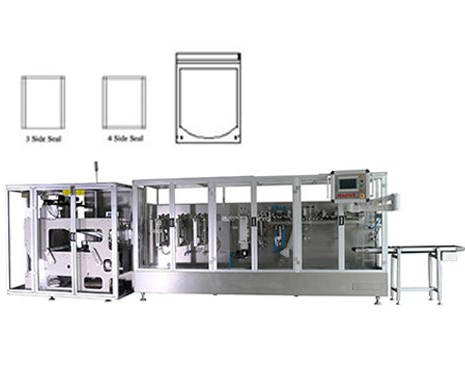

Product Sample:

Machine Features:

- The production efficiency is rapidly increased by holding two rolls of forming foil with large diameter to reduce frequency of replacing material, equipping cut and path station for easy and fast replacing of material, using fast lock method enable replacing of sealing material easily done within 10 seconds, adopting waste foil cutting method enables continuous production elides stop machine to settle waste foil collecting roll.

- Separate the operation zone and transmission zone stops pollution and make daily clean work easier.

- Servo motor enables precise synchronization, feeding length can be randomly set through the HMI.

- Universal mechanism enables Al/Pl (heat forming) switch to Al/Al (code forming) easily by changing moulds and feeder. (Have applying for national patent)

- Big break in feeding method for Al/Al packing enables fast feeding speed for irregular shape tablets.

- Novel mould oriental mechanism satisfied the common request on fast change for moulds.

- Sealing cylinder is put inside machine body to improve machine structure. (Reduce the center of gravity, increase the stability of machine, and have applying for national patent).

- High punch frequency: Al/Pl≤70 punches/min; Al/Al≤50 punches/min.

About the company :

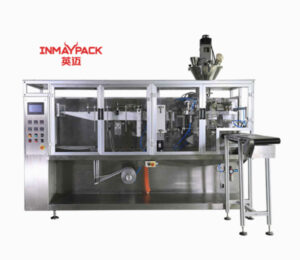

Shanghai Yingmai packaging technology is a high-tech enterprise integrating R & D, production, sales and service of automatic self-supporting bag packaging system. The automatic self-supporting bag packaging equipment is a packaging process system that enables the roll film bag making to form, fill and seal the finished self-supporting bag. It is mainly composed of uncoiler, bag making machine, filling system and sealing device.

The company takes the concept of “leading the development of China’s independent bag packaging technology” as its corporate mission. At present, more than 40 patented technologies and software copyrights have been owned and applied for. The company’s products have passed ISO 9001 international quality system certification, 14001 environmental management system certification and EU CE certification. In the field of self-supporting bag flexible packaging, it has domestic leading R & D and manufacturing capacity and leading technical advantages.

Our exhibition :