Top and edge spout doy pack standup pouch packaging machine

DESCRIPTION

Product Description:

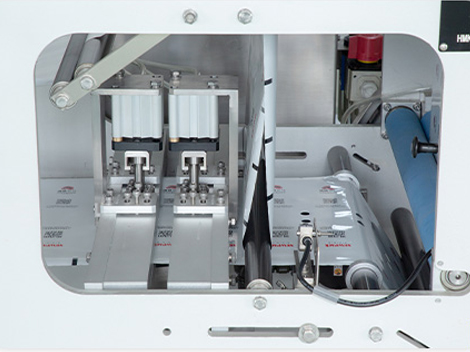

Hmk2600 horizontal self-supporting bag packaging machine adopts the current international popular servo drive technology. The servo motor is used as the drive unit. use

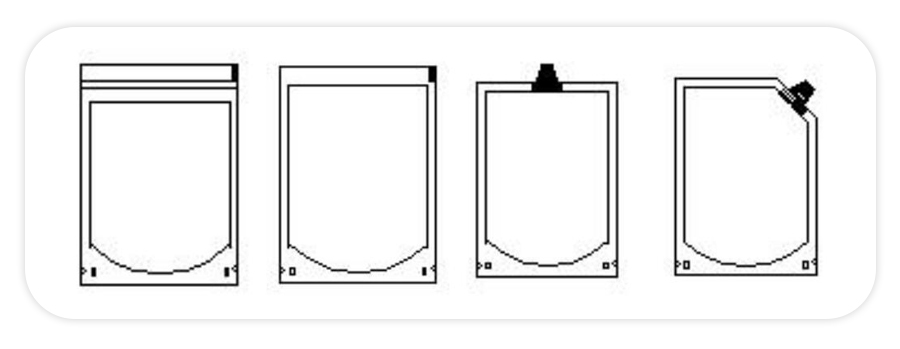

In the production of medium and large flat bags and self-supporting bags, different accessories can be selected to produce zipper bags, positive suction nozzle bags or side suction nozzle bags.

The machine can produce up to 2500ml bags. Suitable for frozen food, snack food, laundry detergent, dried fruit, snacks, candy, oatmeal, etc.

The machine can be equipped with up to four blanking stations for single blanking or multiple blanking as required. You can select single column or double column working mode. When double row bag making is selected, two bags can be generated at the same time in each machine operation cycle. The speed can reach up to 100 bags / min.

The equipment can choose servo screw metering, piston pump metering, measuring cup metering, combined scale metering and other metering methods.

The equipment adopts independent cabinet and independent 12 inch operation panel. Huichuan is used as the standard control system, or Allan Bradley or Beckhoff can be selected.

Technical Parameter:

| HMK-2600 Simplex | ||||

| Machine operation | HFFS | Horizontal form fill and seal | ||

| Technology concept | Pouch origin | Form the reel | ||

| Pouch transport system | intermittent | |||

| Construction | Machine frame | SUS304 apparance | ||

| parts | SUS304 and Aluminum Alloy | |||

| Parts in contact with product | SUS316L /SUS304 | |||

| Reel | Reel diameter | 600mm | ||

| Reel Width | 720mm | |||

| Reel core | 76mm or 158mm | |||

| Machine dimensions | Length×width×height | 6200×1150×2500mm | ||

| Machine weight | 4500Kg | |||

| Pouch dimensions | Length×width×height | Minimum size | Maximum size | |

| Flat bag | 100×120mm | 280×350mm | ||

| Doypack | 100×120×(22+22) | 280×350×(52+52) | ||

| Packaging speed (pouches per minute) And pouch volume (ml) |

Speed maximum(ppm) | Volume maximum(ml) | ||

| Flat bag | 60 | 2000 | ||

| Doypack | 60 | 2500 | ||

| Consumption | Electrical | 11kw | ||

| Air consumption | 300L/min 0.6Mpa | |||

| Electrical Data |

200-415V/50-60Hz/N+G(According to customer requirements customization) |

|||

| model | HMK2000/SZ | HMK2600TS | HMK2600SS | HMK2600D |

| Minimum bag size | 80×120×40 | 80×120×40 | 80×150×40 | 80+80×120×40 |

| Maximum bag size | 260×320×120 | 260×320×120 | 210×320×120 | 130+130×300×80 |

| Bag volume range | 2500ml | 2500ml | 2000ml | 750ml |

| Production speed ppm | 50 | 50 | 40 | 100 |

| Film size range | Maximum diameter 400 mm, core diameter 76 or 152 mm | |||

| Power consumption of equipment | 15Kw | 15Kw | 20Kw | 20Kw |

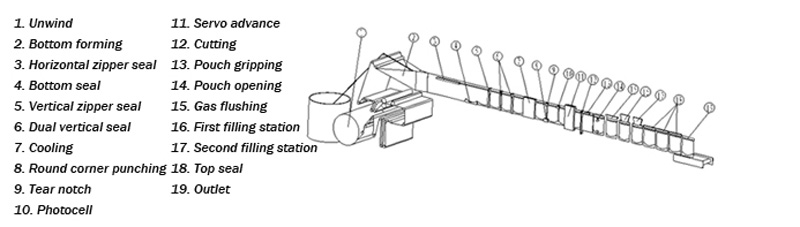

Machine Schematic Drawing (this is for zipper stand up pouch)

Product Samples:

About the company :

Shanghai Yingmai packaging technology is a high-tech enterprise integrating R & D, production, sales and service of automatic self-supporting bag packaging system. The automatic self-supporting bag packaging equipment is a packaging process system that enables the roll film bag making to form, fill and seal the finished self-supporting bag. It is mainly composed of uncoiler, bag making machine, filling system and sealing device.

The company takes the concept of “leading the development of China’s independent bag packaging technology” as its corporate mission. At present, more than 40 patented technologies and software copyrights have been owned and applied for. The company’s products have passed ISO 9001 international quality system certification, 14001 environmental management system certification and EU CE certification. In the field of self-supporting bag flexible packaging, it has domestic leading R & D and manufacturing capacity and leading technical advantages.

Our exhibition :