Mini doypack packaging machine for granule, powder, liquid

DESCRIPTION

Product Description:

Hmk4200 horizontal self-supporting bag packaging machine adopts the current international popular servo drive technology. The magnetic levitation servo motor is used as the driving unit. It is used to produce small flat bags and self-supporting bags.

Suitable for oral liquid, enzyme, jam, powdered sugar, milk powder, candy, etc.

The machine adopts 3x bag discharging or 4x bag discharging technology. Three column or four column operation mode can be selected. Each machine cycle can generate three or four bags at the same time. The speed can reach 320 bags / min.

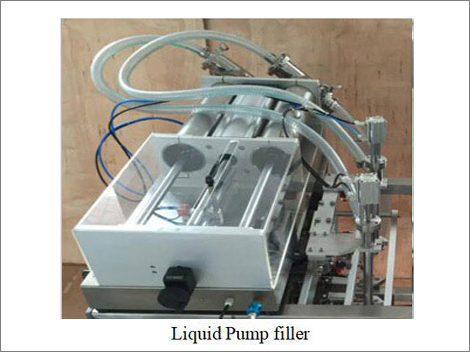

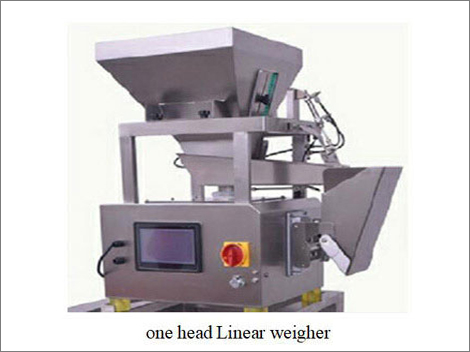

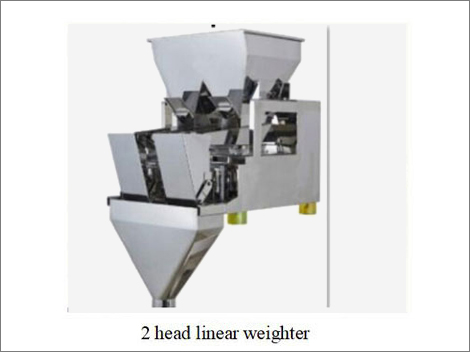

The equipment can choose servo screw metering, servo piston pump metering, gravity flowmeter metering and other metering methods.

The equipment adopts independent cabinet and independent 15 inch operation panel. Huichuan is used as the standard control system, and Allan Bradley or Beckhoff can also be selected.

The equipment adopts integrated cabinet and independent 10 inch operation panel, and the electrical control is integrated in the rack. Siemens is used as the standard control system, and brands such as Mitsubishi or Allan Bradley can also be selected.

Use :

Suitable for packaging granule ,powder ,liquid ,coffee bean ,candy, pet food etc ,food&Non-food

Bag type:

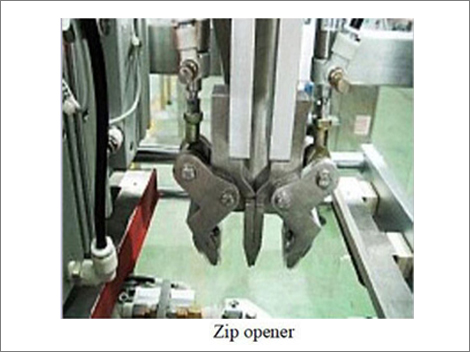

3 side seal bag, stand up pouch/doypack ,zipper bag, box bag, guesset bag

Technical Features:

1. The machine stops running when the safety key interlock switch is pulled out;

2. No bag prompting function;

3. Self-diagnosis function of open the bag failed (The bag can be reused); In that case, the machine will not fill and seal, it will re-take the bag;

4. Positioning (anti-dropping) function of hopper;

5. Warning function of cartridge heater fault;

6. Warning function of cylinder fault.

7. Easy to operate and easy to replace the bag / The machine is suitable for a variety of bag types;

8. Low maintenance cost / Modular replacement of the parts;

Technical data:

| Model | TRC-300 | TRC-430 |

| speed | 6-15 bags / min | 6-15 bags / min |

| Bag size |

Bag width: 90mm ≤ W ≤ 300 mm Bag length: 100mm ≤ length ≤ 300 mm |

Bag width: 100mm ≤ W ≤ 300 mm Bag length: 100mm ≤ length ≤ 430 mm |

| Air consumption | 0.5m3 / min 0.65Mpa; | 0.5m3 / min 0.65Mpa; |

| Machine dimension | L: 1750mm * W:510mm *H: 1300mm | L: 1750mm * W:510mm *H: 1650mm |

| model | HMK4200FET | HMK4200FEQ | |

| Minimum bag size | 60×120 | 60×120 | |

| Maximum bag size | 140×250 | 105×250 | |

| Bag volume range | 600ml | 250ml | |

| Production speed ppm | 240 | 320 | |

| Film size range | Maximum diameter 500 mm, core diameter 76 or 152 mm | ||

| Power consumption of equipment | 25Kw | 25Kw | |

Optional Filling device :

Part Combination :

Workform :

Pouch Samples:

About the company :

Shanghai Yingmai packaging technology is a high-tech enterprise integrating R & D, production, sales and service of automatic self-supporting bag packaging system. The automatic self-supporting bag packaging equipment is a packaging process system that enables the roll film bag making to form, fill and seal the finished self-supporting bag. It is mainly composed of uncoiler, bag making machine, filling system and sealing device.

The company takes the concept of “leading the development of China’s independent bag packaging technology” as its corporate mission. At present, more than 40 patented technologies and software copyrights have been owned and applied for. The company’s products have passed ISO 9001 international quality system certification, 14001 environmental management system certification and EU CE certification. In the field of self-supporting bag flexible packaging, it has domestic leading R & D and manufacturing capacity and leading technical advantages.

Our exhibition :